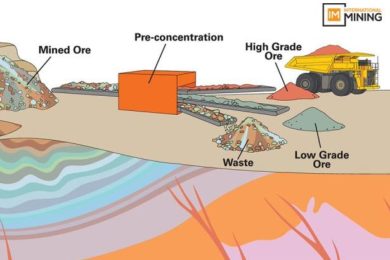

Having outlined a new vendor-agnostic, lab-based “pre concentration screening test” for mining in part one of this three-part series, SRK is back for part two, discussing the wider pre-concentration evaluation process that this testing fits into

“With any pre-concentration analysis, we need to, first, understand the heterogeneity of the deposit; simply put, if you don’t have heterogeneity, you don’t have the ability to separate the good stuff from the bad stuff and carry out pre-concentration,” Bob McCarthy, Principal Consultant, SRK Consulting (Canada) Inc, says.

With this baseline in mind, SRK Consulting has devised a pathway for companies with drill core at their disposal to analyse whether pre-concentration is a viable option for their flowsheet.

Made up of five steps, this staged approach is deliberately designed to allow companies to pause at the end of each phase to re-evaluate if there is a strong enough case to continue investing the time and finances required.

The heterogeneity analysis is first up, which, under SRK’s evaluation, includes two different approaches based off drill hole analysis: Heterogeneity and Scale and Composite-Sample Relationship Analysis.

“Heterogeneity and Scale involves a process of looking up and down the bore hole at different aggregation distances from every sample and interrogating the sample grade – or net smelter return – against the aggregations above and below that individual sample,” he explains. “We then increase the size of the aggregation to see how that relationship changes.”

Such analysis enables SRK experts to derive the heterogeneity measures typically dubbed ‘waste in ore’ (mineralisation below the cutoff grade within an above cutoff grade zone) or ‘ore in waste’ (mineralisation above the cutoff grade within a waste or marginally below cutoff grade zone). Using a cutoff grade derived from industry benchmarking, the consultants assess the aggregation distance, as resolved in the vertical direction, with the “selective mining unit” (SMU), which typically relates to equipment sizing for mining.