Bluhm Burton Engineering (BBE) Projects recently completed the commissioning of a 1.7MWR underground Bulk Air Cooler (BAC) situated on the 63 level at Tshepong North Operations, near the town of Welkom in South Africa, on behalf Harmony Gold Mining Company Limited (Harmony). The installation of the BAC was required as part of the mine’s strategic plan to improve underground working conditions in their decline. Tshepong North is an established underground mining operation that uses conventional undercut mining techniques. The primary gold-bearing orebody targeted by Tshepong North and South operations is the Basal Reef, supplemented by the extraction of the B Reef as a high-grade secondary reef. Mining activities are conducted at depths ranging from 1 500 meters to 2 300 meters. The extracted ore undergoes processing at the Harmony One plant, where gold is recovered using the gold cyanide leaching process.

The BAC supplied, constructed, and commissioned by BBE Projects is a two-stage cross flow horizontal spray chamber, incorporating banks of sprayers that release tiny droplets of chilled water vertically into the air stream through spray nozzles. The thermal performance of the BAC is significantly enhanced by employing a two-stage configuration, in which air to water contact is doubled in the chamber. Air flow through the BAC is achieved by the mine’s underground booster fans so dedicated BAC fans did not have to be installed, minimising capital and operating costs.

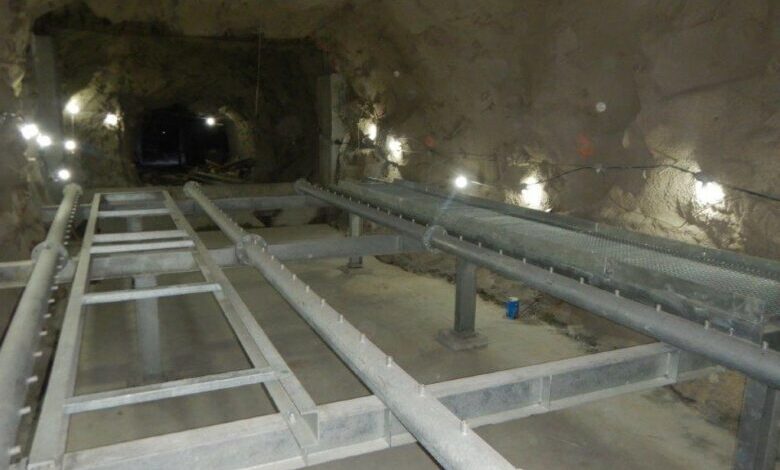

Easy access to the spray nozzles in the spray chamber for maintenance and inspection purposes is made possible by installing hot-dip-galvanised steel walkways between the spray pipes. The BAC floor is constructed from concrete and appropriately graded to facilitate the annual cleaning process. Where cool air emerges from the spray chamber, mist eliminators have been installed to capture droplets, preventing water carry-over into the haulage. The mist eliminator blades are formed from a specially formulated fire-retardant material developed by BBE, to ensure optimal operational safety.

Chilled water is supplied from the mine’s existing chilled water circuit and the supply flow rate is maintained at a constant rate by a flow control valve, regardless of the mine’s fluctuating consumption of chilled water in other areas. The BAC is equipped with operating and standby pumps for spraying the chilled water and returning it to the mine water circuit. The return water pumps are fitted with Variable Speed Drives (VSDs) to maintain the water level in the BAC regardless of the rate of water condensation in the BAC and the slight possibility of fluctuations in chilled water supply.

In line with Harmony’s ethos of “mining with purpose”, Harmony identified the need for BBE to modify the return water system design to allow slightly warmer chilled water to be reused on lower levels if operations demand it, or returned to the settlers for pumping to surface. This was achieved by using a control valve to regulate the flow of return water between the lower levels and settlers on the BAC level. The return pipeline is also fitted with mechanical pressure relief valves and pressure sensors to prevent an overpressure scenario. This strategy improves service water pressure on levels (below 63 level) and results in cost saving. The saving is realised because of the water being reused therefore less water needs to be dewatered and refrigerated on surface.

The BAC is located 1.6 kilometers from the shaft on 63 Level and is supplied with chilled water from the mine’s existing chilled water circuit at a nominal flowrate of 75 liters per second. The design of the BAC ensures flexibility and caters for an increased cooling duty should the mine decide to construct an underground refrigeration plant on 66 Level in future, which would then be used to supply the BAC on 63 Level with chilled water. Currently, 1000 liters per second of chilled water is produced by a surface cooling installation, which comprises four refrigeration plants with a total cooling capacity of 39MWR. A surface BAC consumes 400 liters per second of chilled water, and the balance is distributed underground via a chilled water supply pipe column installed in the shaft with pressure relief valve (PRV) stations on various levels.

“The commissioning of the underground Bulk Air Cooler at Tshepong North Operations stands as a testament to BBE Projects’ engineering expertise and highlights the importance of a collaborative partnership with Harmony to ensure the success of the project. This innovative solution not only enhances operational efficiency but also contributes to a sustainable and environmentally conscious approach to mining practices.”Avinash Andhee, Project Engineer at BBE

Previously, air cooling on 63 level was provided by a bank of closed-circuit coils located near a sub-vertical shaft which fed cool air to the lower levels. The new open-circuit horizontal spray chamber BAC replaces the coil bank as it has many operating and capital cost advantages. Maintenance of the open-circuit BAC is significantly simpler than for a coil bank, and maintenance frequency is considerably lower as it is not prone to fouling at the air-water heat exchange interface. Moreover, the air pressure drop across an open-circuit BAC is considerably lower than a coil bank, minimising electrical power absorbed by the booster fans and thus, operating costs. Furthermore, the enhanced design allows for a better cooling duty to be achieved with an improved air flow rate.

Harmony issued an enquiry for a turnkey contract to build the underground bulk air cooler, in 2021. The BBE tender covered all technical, commercial, and statutory requirements laid out in the enquiry documents and BBE Projects was awarded the contract on a competitive basis, after a few rounds of technical and commercial queries. BBE Projects carried out detailed design, procurement, manufacturing, quality control, shipping, delivery, construction, erection, installation, supervision, project management, commissioning, testing, certification and hand-over of the BAC.

“Through our collaboration with BBE Projects on our Underground Bulk Air Cooler installation, we at Harmony continue to drive forward-thinking solutions for underground environmental management. This partnership reflects our dedication to operational excellence and environmental sustainability, setting a benchmark for responsible mining practices in our industry.”Kasper Oberholzer, Engineering Manager at Harmony Gold Mining Company – (Tshepong North)

All civil, structural, mechanical, and Electrical, Control, and Instrumentation (EC&I) works were carried out by contractors in line with the mine’s commitment to drive local socio-economic development and training. Site construction, erection and assembly was supervised by BBE Projects with regular inspections by discipline-specific engineers from BBE and Original Equipment Manufacturers (OEMs).

A major challenge in executing underground construction projects is getting material, equipment, and personnel to the underground work areas timeously and safely, given the many competing demands for use of the mine’s shaft conveyance. This challenge was overcome by establishing clear lines of communication among all project stakeholders and proper planning as well as regular project meetings with the mine to discuss progress, challenges, and solutions. With this constraint in mind, BBE aimed to design components required to construct the BAC, as much as possible, in sections that could fit into a cage rather than being slung beneath it, which is far more time consuming.

BBE Projects has been assisting Harmony with ventilation and refrigeration upgrades at Tshepong North and South operations for the past few years with a major improvement in underground environmental conditions. The first project was a booster fan station on 66 level at Tshepong South Operations (formerly known as Phakisa) in 2019. Since then, BBE has successfully commissioned an underground condenser fan station on 55 level at Tshepong South and two more booster fan stations at Tshepong North Operations on 66 level.